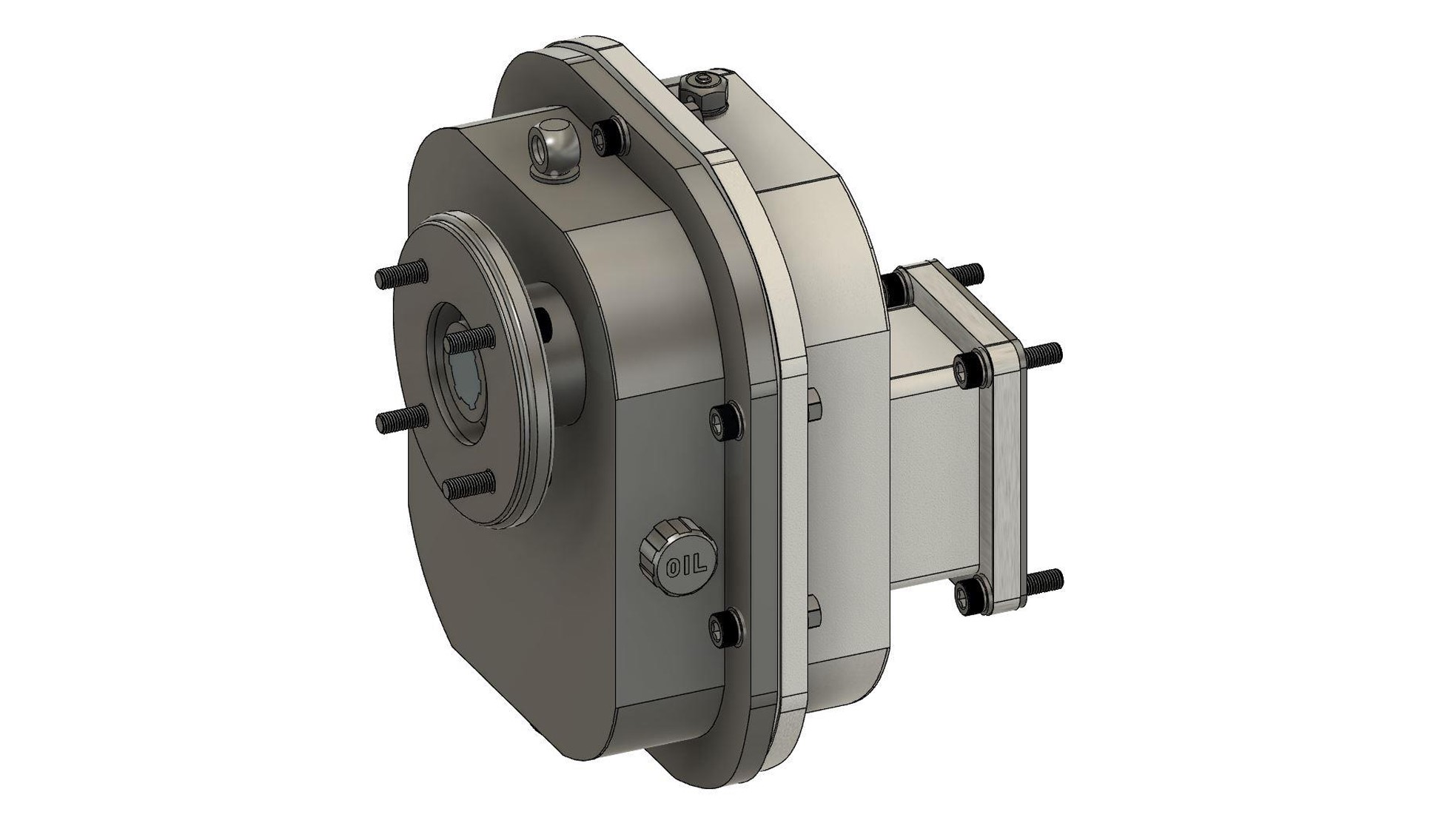

Our team designed a PTO (Power Take-Off) speed reduction unit to bring a 45kW diesel engine’s speed from a whirlwind 2800 rpm to a steady 1300 rpm, making it perfect for powering hydraulic systems. The goal? Reliable performance with durability and easy upkeep.

Maintenance? Piece of Cake. With this PTO unit, maintenance isn’t something you dread—it’s part of the fun! We designed the unit with user-friendliness in mind, so there's no need for complicated tools or an engineering degree to keep it running smoothly. A simple oil change every 2500 hours, a bit of greasing here and there, and this unit will keep humming along happily. It's like the car maintenance version of “set it and forget it,” but for industrial machinery.

And of course, here is why you'll love our PTO:

This PTO speed reduction unit offers reliable power transfer, long-lasting durability and easy maintenance—all while making your life a little easier.

Now that we’ve cruised through the timeline, let’s dive into the design report—where the gears start turning, and the engineering brilliance really kicks into high gear.

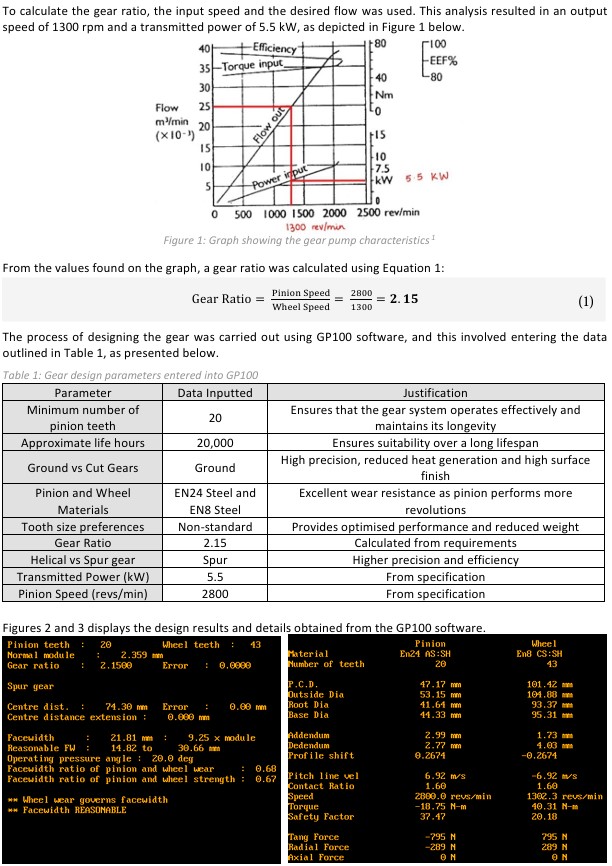

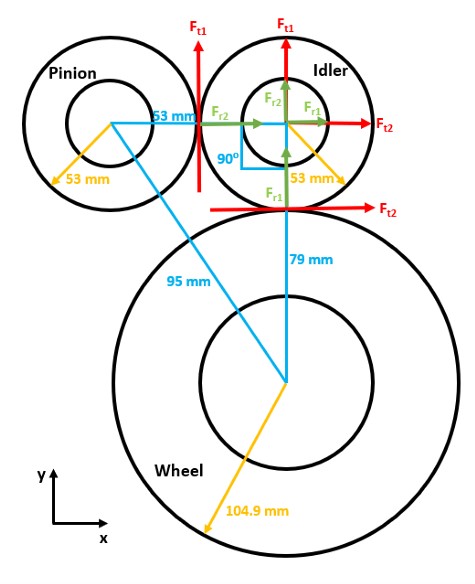

When it comes to gear design, it's all about turning that engine power from a 2800 rpm sprint into a smooth, manageable 1300 rpm jog—thanks to our perfectly calculated 2.15:1 gear ratio.

We didn’t just grab any old gears off the shelf. These are made from EN24 steel for the pinion and EN8 steel for the wheel, because durability is key when you’re dealing with the kind of power that could easily turn metal into mush.

Using GP100 software (and a few cups of coffee), we crunched the numbers on everything from the number of teeth to the perfect tooth size. The result? Gears that are tough enough to handle anything, while staying cool under pressure. And they’ll keep turning smoothly for up to 20,000 hours.

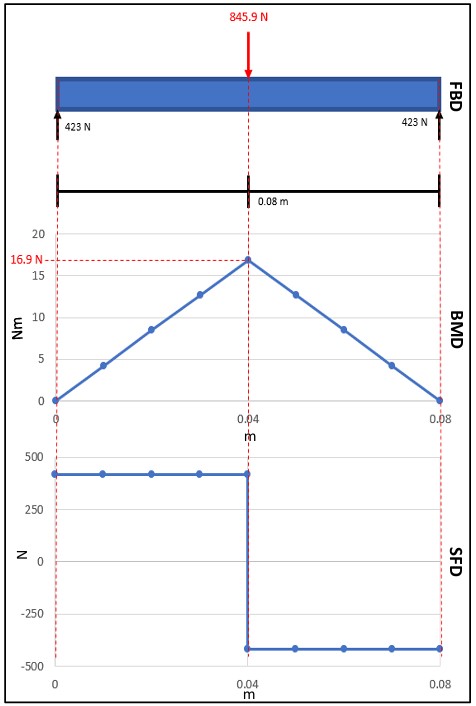

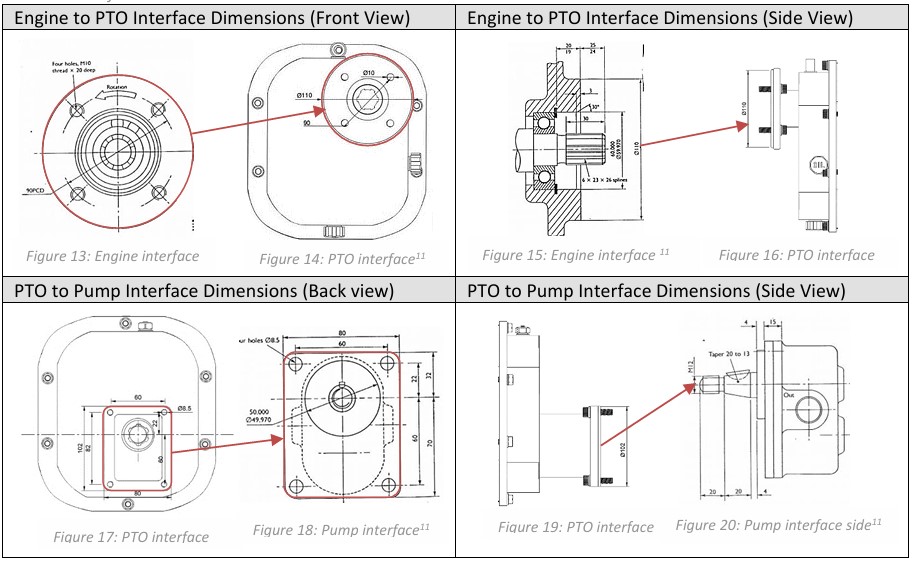

Connecting the engine, PTO unit and pump wasn’t just about bolting things together—it was all about precision.

Standard dimensions and bolt threads ensured the parts fit together, reducing any chance of a misstep.

The interface design made it easy for maintenance and replacement, while ensuring perfect alignment so everything runs smoothly, without any awkward wobbles or breakdowns.

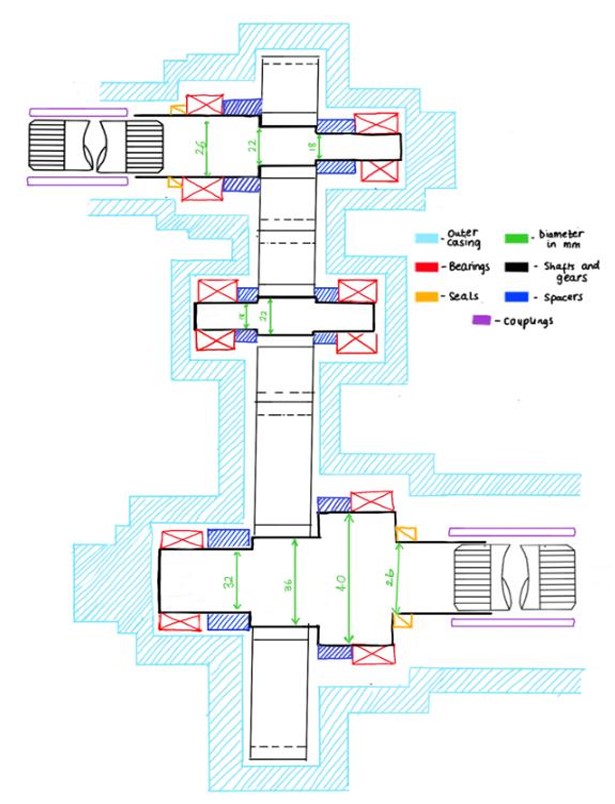

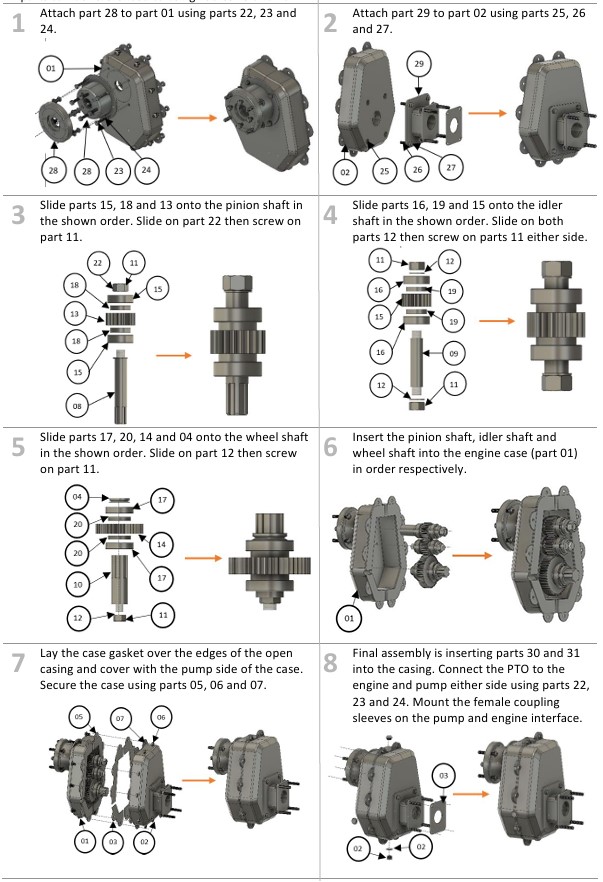

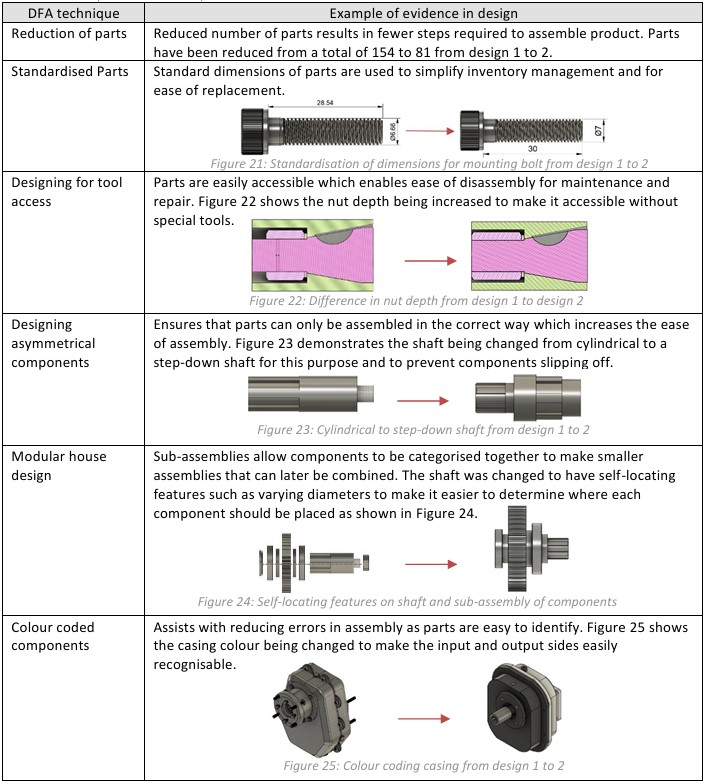

When it comes to putting the PTO unit together, simplicity was key. We designed everything to fit like a puzzle—fewer parts, standardised shapes and easy access for tools meant less frustration and faster assembly.

Our modular sub-assemblies slotted together perfectly, with colour-coded components to keep even the most distracted assembler on track.

By focusing on tool accessibility and self-aligning features, we made sure that anyone could assemble (and disassemble) the unit without needing a PhD in mechanical engineering—or a magic wrench.

With the design all mapped out, it’s time to see how it comes together—welcome to the assembly drawings, where every nut and bolt finds its perfect place.

And there you have it—from initial sketches to fully assembled precision. We’ve tackled every challenge, and now, this PTO unit is ready to keep the wheels of industry turning smoothly!